A Single Axis Shredder for HDPE PVC Plastic is widely used in recycling and waste processing industries.They can shred Plastics (films, pipes, lumps, injection molding waste).The single shaft shredder can shred 600-1200kg of HDPE and PVC per hour.

Payment :

LC/DP/TTPackaging Details :

Wooden CaseShipping Port :

ShanghaiLead Time :

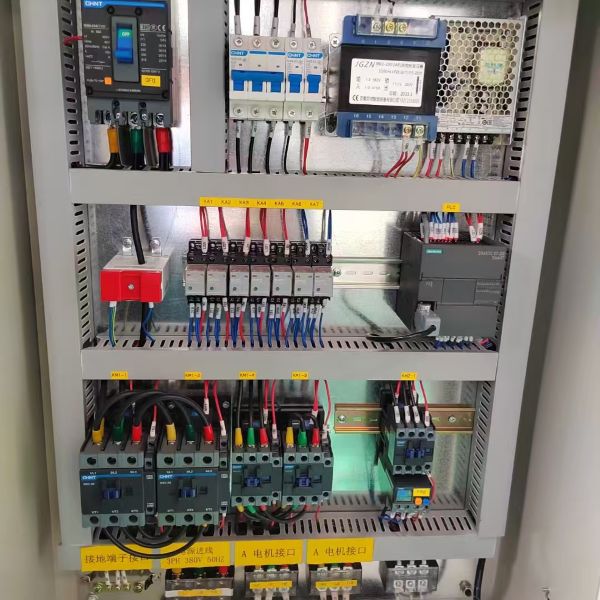

10 DaysControl System :

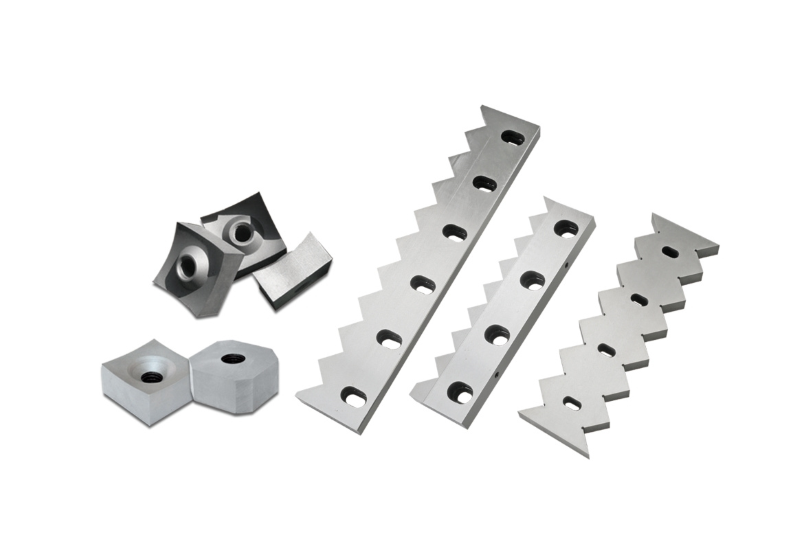

PLC ControlBlade Material :

SKD11,55sicr, 9crsi, 6crw2sFunction :

Multifunctional Waste Material Shredder

Advantage

The single shaft shredder machine is a versatile and efficient tool for reducing the size of various materials. It offers several advantages over other types of shredders, making it a popular choice for industrial and commercial applications.

• Efficiently

Single shaft shredders are designed to work quickly and efficiently, reducing the size of materials in a single pass.

• Stably

Single shaft shredders produce a consistent output size, ensuring that materials are shredded to a uniform size.

• Safely

Single shaft shredders are equipped with safety features such as emergency stop buttons, guards, and safety sensors to protect operators from accidents.

The blade features a simple structure for easy maintenance, saves space, and has low cost. It can also handle soft materials in a targeted manner and be customized according to materials.

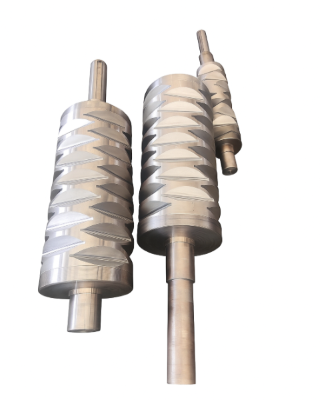

The single shaft can reduce soft material entanglement, handle soft materials in a more targeted manner, and directly adjust the load to adapt to a single type of material for optimized crushing.

The pusher can significantly improve feeding and crushing efficiency, prevent material deviation, feature low maintenance costs, ensure operational safety, and reduce manual intervention.

The power unit requires no dual-shaft synchronization, featuring low cost, easy maintenance, and small space occupation. It can directly adjust the load with reasonable energy consumption.

Product Parameters

These features ensure excellent performance, which is reflected in the following technical specifications:

| Model | 600 | 800 | 1000 |

| Overall dimensions(MM) | 1840*1379*1754 | 2500*1712*1700 | 2838*2036*1880 |

| Size of feed inlet(MM) | 857*600 | 1200*800 | 1410*1000 |

| Discharge height(MM) | 546 | 500 | 500 |

| cylinder stroke(MM) | 500 | 750 | 900 |

| Rotor diameter(MM) | Φ224.7 | Φ300 | Φ390.3 |

| Rotor length(MM) | 600 | 700 | 800 |

| Spindle speed(RPM) | 83 | 83 | 74 |

| Mesh hole(MM) | Φ25 | Φ40 | Φ40 |

| Moving knives(PCS) | 32 | 46 | 58 |

| Fixed knives(PCS) | 2+2 | 2 | 2 |

| Motor power(KW) | 18.5 | 30 | 45 |

| Hydraulic power(KW) | 2.2 | 2.2 | 2.2 |

| Hopper capacity(L) | 760 | 1100 | 1500 |

| Equipment weight(KG) | 1600 | 2600 | 3900 |

Application

Single shaft shredders can process a wide range of materials, including plastics, wood, rubber, paper, and metal. This makes them ideal for industries that have diverse shredding needs.

Certifications

leave a message

Scan to wechat :

Scan to Whatsapp :